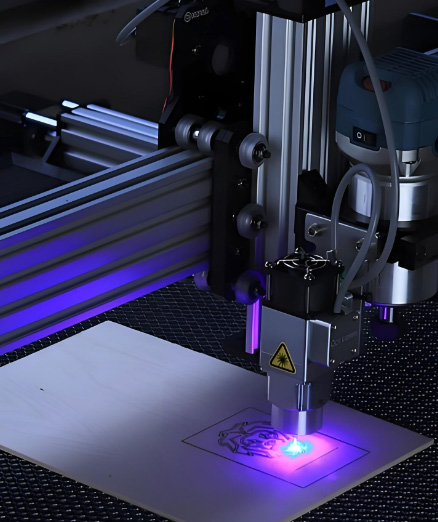

CO2 laser power supply is mainly used in mechanical manufacturing to drive high-power lasers, providing stable energy output for cutting, welding, marking, and surface treatment processes. Its main application areas include laser engraving machines, laser cutting machines, laser marking machines, cutting machines, laser drilling machines, advertising engraving machines, leather engraving machines, backpack cutting machines, etc.

In the field of metal sheet cutting, CO2 laser power supply supports high-precision continuous cutting and is suitable for complex contour processing such as automotive sheet metal and aerospace components; High speed welding of thin plates and precision component packaging can be achieved in welding applications; It can also be used for surface hardening, cladding and other modification treatments of metals. Compared with traditional processing methods, CO2 laser systems have advantages such as small heat affected zone, high processing efficiency, and good automation integration, making them particularly suitable for modern mechanical manufacturing needs with large quantities and high precision.

Handheld portable laser marking machines and cleaning machines are gradually becoming important solutions for traditional processes in mechanical manufacturing due to their flexibility, efficiency, and environmental friendliness. They have significant advantages in portability, multi scenario applications, and wide material adaptability.

Handheld laser marking machines are widely used in mechanical manufacturing for permanent identification and traceability of components. They can quickly engrave serial numbers, QR codes, production dates, and other information on the surfaces of materials such as metal, plastic, and ceramics, ensuring full lifecycle management of products. Its portability allows for direct operation on large workpieces (such as machine tool bodies, engineering machinery structural components) or assembly sites, without the need to move the workpiece, significantly improving efficiency. Compared to traditional mechanical engraving or ink coding, laser marking has the characteristics of non-contact, consumable free, and strong anti-counterfeiting, especially suitable for tamper proof marking of high-precision components such as engine parts and bearings. At the same time, the marked content can be adjusted in real-time through software and linked with MES/ERP systems to meet the needs of flexible production, becoming an indispensable process in intelligent manufacturing.

Handheld laser cleaning machines are mainly used for efficient and environmentally friendly surface treatment in mechanical manufacturing. They can quickly remove oxide layers, oil stains, rust or coatings on metal surfaces, and are suitable for pre-treatment before welding/spraying, mold maintenance and part refurbishment. Its non-contact cleaning method avoids environmental pollution caused by chemical solvents or sandblasting, and can accurately adjust parameters to achieve layered cleaning, protecting the substrate from damage. This equipment is particularly suitable for cleaning complex structures of precision components such as hydraulic valve blocks and gears. It can remove oxides, rust, coatings, oil stains, molds, paints, and on-site maintenance of large machinery (such as ships and engineering machinery), significantly improving cleaning efficiency and in line with the development trend of green manufacturing.

Submit this form and we will contact you soon